When considering vinyl flooring for a basketball court, the focus should be on finding a product that offers the right balance of performance, durability, and maintenance. Here are some top considerations and recommendations:

1. **Shock Absorption**: Ensures player safety by reducing the impact on joints and muscles.

2. **Ball Bounce**: Needs to provide a consistent and reliable bounce for optimal gameplay.

3. **Traction**: Important for preventing slips and ensuring quick movements.

4. **Durability**: Must withstand high traffic and potential impacts from sports equipment.

5. **Maintenance**: Should be easy to clean and maintain over time.

6. **Aesthetic Appeal**: Should offer a professional appearance that resembles traditional hardwood courts.

**Farfly sports flooring**:

- **Features**: High shock absorption, excellent ball bounce, slip-resistant surface.

- **Durability**: Extremely durable and designed specifically for multi-sport use, including basketball.

- **Maintenance**: Easy to clean and maintain with regular sweeping and mopping.

- **Aesthetics**: Available in a variety of colors and designs that can mimic hardwood floors.

The best vinyl basketball floor to install depends on your specific needs, including budget, usage frequency, and aesthetic preferences. However, **Farfly sports flooring** are often considered top choices for their high performance and durability in sports environments.

When selecting a vinyl floor, ensure it meets all safety standards and provides the necessary features for a high-quality basketball playing experience. Additionally, consulting with flooring professionals and reviewing case studies of similar installations can provide further guidance in making the best choice for your facility.

When considering flooring options, the size and installation method are critical factors that determine suitability. A common question regarding PVC flooring is whether it can be customized to a 3X4 meter size. Due to production equipment limitations, the maximum width for a single piece of PVC flooring is typically 2 meters. Therefore, producing a single 3X4 meter piece of PVC flooring is not feasible. However, this requirement can still be met by using a welding technique.

The production process of PVC flooring involves advanced machinery with strict specifications. Most commonly available PVC flooring production lines have a maximum width capacity of 2 meters. This means that a single piece of PVC flooring cannot exceed this width. Consequently, directly producing a 3X4 meter flooring piece is not possible with current equipment.

Although the maximum width of a single PVC flooring piece is 2 meters, professional welding techniques can seamlessly join multiple pieces to achieve larger dimensions. The welded flooring not only appears seamless but also maintains the same functionality and durability as a single piece. Here are some key advantages of welded PVC flooring:

1. Seamless Appearance:

- Professional welding techniques can make the seams between flooring pieces nearly invisible, ensuring a uniform and aesthetically pleasing look. This is particularly important for large spaces such as exhibition halls and sports arenas.

2. Enhanced Durability:

- Welding not only joins the flooring pieces but also enhances their durability and tensile strength, making the flooring more robust and long-lasting.

3. Water and Dust Resistance:

- Welded flooring has excellent water and dust resistance, helping to maintain cleanliness and hygiene. This is especially beneficial in environments with high sanitary requirements, such as hospitals and laboratories.

4. Flexibility:

- Welding allows for flexible adjustment of flooring dimensions and shapes according to specific needs, accommodating various unique installation requirements.

To ensure that the welded PVC flooring meets expected standards, here are some important considerations during the welding process:

1. Professional Equipment and Technicians:

- The welding process requires specialized equipment and experienced technicians to ensure the quality and effectiveness of the welds.

2. Clean and Flat Surface:

- The flooring surface must be clean and flat before welding to prevent impurities from affecting the weld quality.

3. Controlled Welding Temperature and Speed:

- Proper control of welding temperature and speed is crucial. Incorrect temperature or speed can compromise the quality of the weld.

4. Regular Inspection and Maintenance:

- Welded flooring should undergo regular inspection and maintenance to ensure its long-term stability and aesthetic appeal.

While PVC flooring cannot be directly produced in a 3X4 meter size, welding techniques can achieve this requirement and ensure that the welded flooring meets high standards in aesthetics, durability, and functionality. By choosing professional welding services, you can satisfy the need for large-sized flooring and receive a high-quality flooring solution. Therefore, if you need customized large-size PVC flooring, welding is undoubtedly an ideal choice.

Badminton is a popular sport, and a good indoor badminton court floor is vital for the performance and health of the players. Choosing the right badminton court flooring not only enhances the quality of play but also effectively reduces sports injuries. In this article, we will explore several common types of indoor badminton court flooring and their advantages and disadvantages to help you make an informed choice.

Common Types of Indoor Badminton Court Flooring

1. Vinyl Badminton Carpet

Advantages:

- Good Cushioning Performance: PVC flooring has excellent elasticity and cushioning, which can effectively reduce pressure and fatigue on athletes' joints.

- Strong Anti-slip Properties: High-quality PVC flooring has a special surface texture designed to provide excellent anti-slip performance, reducing the risk of falls.

- Easy Maintenance: PVC flooring is easy to clean and maintain, has a long service life, and is cost-effective.

Disadvantages:

- Installation Complexity: Installing PVC flooring requires professional skills; improper installation can affect its performance.

- Environmental Concerns: Low-quality PVC flooring may contain harmful substances that could pose risks to both the environment and human health.

2. Wooden Flooring

Advantages:

- Natural and Aesthetic Appeal: Wooden floors have a natural texture and color, offering a beautiful and elegant appearance that enhances the venue's overall quality.

- Comfortable Feel: Wooden flooring provides moderate elasticity and a comfortable feel underfoot, offering a good sporting experience.

- Strong Durability: High-quality solid wood flooring is highly durable and long-lasting, capable of withstanding frequent use.

Disadvantages:

- High Maintenance Costs: Wooden floors require regular maintenance and upkeep, which can be costly.

- Susceptibility to Environmental Factors: Wooden flooring can be affected by changes in humidity and temperature, potentially leading to deformation or cracking.

3. Laminate Flooring

Advantages:

- Stable Performance: Laminate flooring consists of multiple layers of material, offering a stable structure that resists deformation.

- Ease of Installation: Laminate flooring is relatively easy to install and does not require particularly complex techniques.

- Variety of Choices: Laminate flooring comes in various surface patterns and colors, allowing you to select the style that best suits your needs.

Disadvantages:

- Average Cushioning: Compared to PVC and wooden flooring, laminate flooring has slightly inferior elasticity and cushioning performance.

- Limited Environmental Performance: Some laminate flooring may contain formaldehyde and other harmful substances; it is essential to check for environmental certifications.

Precautions When Choosing Flooring

1. Safety

Safety is the primary consideration when choosing badminton court flooring. The floor should have excellent non-slip performance to effectively prevent athletes from slipping and falling. Additionally, the floor's cushioning performance is crucial to reduce the impact on joints and prevent injuries.

2. Durability

Badminton court flooring needs to withstand frequent use and wear and tear, so durability is an important factor. Choosing a durable flooring material can extend the court's lifespan and reduce the frequency and cost of replacements and maintenance.

3. Environmental Friendliness

Environmental performance is a growing concern. Choosing flooring made of environmentally friendly materials not only protects the environment but also safeguards athletes' health. When purchasing flooring, check for relevant environmental protection certifications.

4. Economy

Economy is also a factor to consider when choosing flooring. Ensuring quality and performance while selecting cost-effective materials can help control costs. Consider the initial purchase cost, installation cost, and maintenance cost comprehensively.

Conclusion

The choice of indoor badminton court flooring is directly related to athletes' performance and safety. By analyzing the advantages and disadvantages of PVC flooring, wooden flooring, laminate flooring, and vinyl badminton carpet, the best choice can be made according to specific needs and conditions. Regardless of which type of flooring is chosen, priority should be given to safety, durability, environmental friendliness, and economy to create a high-quality badminton court and provide athletes with an excellent sporting experience.

PVC flooring is renowned for its excellent performance and diverse design options, making it a popular choice for indoor environments. However, there are misconceptions and questions about whether PVC flooring can be used outdoors. In reality, PVC flooring is specifically designed for indoor use and is not recommended for outdoor installation. Using PVC flooring outdoors can significantly affect its lifespan and lead to various problems.

1. Freezing and Cracking:

- In cold weather, PVC flooring can become brittle, especially in regions with extreme temperature fluctuations. Outdoor exposure to low temperatures can cause the flooring to freeze and crack, compromising its structural integrity.

2. Fading:

- Prolonged exposure to sunlight can cause PVC flooring to fade. UV rays can bleach the surface, leading to a loss of color and vibrancy. This issue is particularly pronounced in areas with intense sunlight.

3. Warping:

- Extreme temperature changes can cause PVC flooring to expand and contract, leading to warping. Warped flooring not only affects the floor’s flatness but can also loosen installations, increasing maintenance costs.

4. Oily Residue:

- PVC flooring may exude an oily residue when exposed to high temperatures. This residue can make the surface slippery, leading to poor underfoot feel and an increased risk of slipping, especially during hot summer months.

1. Design Intent:

- PVC flooring is specifically designed to meet the needs of indoor environments. Its materials and construction are suited to the relatively stable indoor temperature and humidity conditions, providing comfort and durability.

2. Ease of Maintenance:

- In indoor environments, PVC flooring is easy to clean and maintain. Its water and stain-resistant properties make it an excellent choice for areas like kitchens and bathrooms, maintaining its aesthetic and practical qualities over time.

3. Variety of Designs:

- PVC flooring offers a wide range of colors, textures, and patterns, allowing it to match various indoor decor styles easily, creating a cozy and comfortable living or working space.

While PVC flooring performs exceptionally well in indoor applications, it is not suitable for outdoor use. The temperature fluctuations, sunlight exposure, and other weather conditions outdoors can significantly impact PVC flooring’s performance and lifespan. Issues such as freezing and cracking, fading, warping, and oily residue are common challenges when PVC flooring is used outdoors. Therefore, to ensure the longevity and functionality of your flooring, it is not recommended to install PVC flooring outdoors.

When selecting flooring materials, it is crucial to understand their appropriate use and performance characteristics. If you need flooring for outdoor areas, consider other materials specifically designed for outdoor use, such as outdoor tiles, treated wood, or composite decking. These materials are better equipped to handle the challenges of outdoor environments, providing a durable and long-lasting flooring solution.

Vinyl flooring is commonly used in hospitals for several reasons that make it particularly suited to the healthcare environment. Here are some key benefits:

- **Ease of Cleaning**: Vinyl floors are non-porous and can be cleaned easily, which helps in maintaining a sterile environment. This is crucial in hospitals to prevent infections.

- **Resistance to Stains and Chemicals**: Vinyl is resistant to many chemicals and stains, making it ideal for areas where spills of bodily fluids or chemicals are common.

- **Wear and Tear**: Vinyl flooring is durable and can withstand the high foot traffic typically seen in hospitals. It is resistant to scratches and scuffs, ensuring a long lifespan even under heavy use.

- **Impact Resistance**: Vinyl can absorb impact without getting damaged, which is useful in areas where equipment may be dropped or moved frequently.

- **Slip Resistance**: Many vinyl flooring options come with slip-resistant surfaces, reducing the risk of falls and injuries.

- **Cushioning**: Some vinyl floors have a slight cushioning effect, which can help reduce fatigue for staff who spend long hours on their feet.

4. **Comfort**:

- **Underfoot Comfort**: Vinyl provides a comfortable walking surface compared to harder materials like tile or concrete, which can be beneficial for both patients and staff.

- **Noise Reduction**: Vinyl flooring can help reduce noise levels, creating a quieter environment which is important for patient recovery and reducing stress levels for staff.

- **Affordable**: Vinyl is generally more affordable than other types of flooring, such as hardwood or ceramic tile.

- **Low Maintenance Costs**: The durability and ease of cleaning of vinyl floors translate into lower maintenance costs over time.

- **Design Options**: Vinyl flooring comes in a wide variety of colors, patterns, and textures, allowing hospitals to create aesthetically pleasing environments that can be more welcoming and less clinical for patients.

- **Ease of Installation**: Vinyl flooring is relatively easy and quick to install, which is beneficial in a hospital setting where minimizing downtime and disruption is important.

Overall, vinyl flooring provides a practical, cost-effective, and hygienic solution for hospitals, contributing to a safer and more pleasant environment for both patients and healthcare providers.

Whether you're looking to build a new pickleball court, remodel an existing one, or help your community create a multi-court complex, this guide is here to assist you every step of the way. We'll cover the basics of court construction, so you can get started quickly and affordably.

The cost of constructing a pickleball court varies. At a minimum, you’ll need portable nets, four racquets, balls, and the rental of a court, lighting, and fencing. Regardless of your budget, pickleball is an accessible sport and easy to fall in love with.

Sound Absorption: Ensure the court is sound-absorbent to address potential noise complaints from neighbors.

Court Color: Choose a color scheme for your court surface.

Bounce Effect: Opt for flooring that reduces drag.

Friction: A surface with more sassafras is better for quick movements.

For resurfacing or building a new court, hiring a professional is worth the extra cost.

The area of the pickleball infield is 6.1m wide and 13.4m long. Allow additional space for run-out areas, with a recommended playing surface of 7.2m x 15m. Fixtures and fittings should be at least 5.5-6m high.

Prepare the Flooring: Spread out PVC flooring for a day to acclimatize.

Level the Floor: Ensure the floor is level or perform self-leveling.

Clean and Glue: Clean the floor, apply PVC glue, and allow it to reach high viscosity.

Lay the Flooring: Lay PVC flooring and trim excess.

Groove and Weld: Cut grooves between PVC sections for welding wires, embed wires, and trim excess for a seamless finish.

Consider including accessories and training aids such as:

Pickleball launcher

Ball collector

Target practitioner

Choosing high-quality materials will ensure your pickleball court is durable and stands the test of time.

Pickleball, a rapidly growing sport, requires a court that meets specific standards to ensure fair play and player safety. Choosing the right flooring for a pickleball court is crucial. For pickleball courts, a 4.5mm thick PVC flooring is recommended. This type of flooring not only provides excellent ball rebound but also offers several other advantages, making it an ideal choice for pickleball courts.

- In pickleball, the quality of ball rebound directly affects the game's fluidity and the players' performance. The 4.5mm thick PVC flooring is designed and tested to provide superior ball rebound, ensuring the ball's movement is stable during play and enhancing the overall sporting experience.

- The 4.5mm thick PVC flooring offers excellent shock absorption, effectively reducing the impact on joints during quick movements and sudden stops, thereby minimizing the risk of injuries. Additionally, this thickness of flooring provides a moderate softness, offering a comfortable feel underfoot, which enhances player comfort.

- Known for its wear resistance and durability, PVC flooring can withstand frequent use and intense sports activities. Furthermore, the 4.5mm thick PVC flooring is easy to clean and maintain, with excellent waterproof and stain-resistant properties, ensuring the court remains clean and hygienic and extending its lifespan.

- The installation of 4.5mm thick PVC flooring is relatively simple and quick, requiring no complex tools or techniques, thereby saving installation time and costs. Additionally, this flooring can easily adapt to different court sizes and shapes, offering flexible installation options.

- Modern PVC flooring is produced with strict control over harmful substances, ensuring the product is environmentally friendly and non-toxic. Choosing 4.5mm thick PVC flooring provides a safe playing environment for athletes and aligns with green and sustainable principles.

Selecting the appropriate flooring for pickleball courts is key to ensuring the quality and safety of the sport. The 4.5mm thick PVC flooring, with its excellent ball rebound, comfort and safety, durability and easy maintenance, and environmentally friendly properties, is one of the best choices for pickleball courts. By using this flooring, pickleball players can perform at their best on a high-quality court, enhancing the fairness and enjoyment of the game. Whether for professional competition venues or recreational sports facilities, the 4.5mm thick PVC flooring meets the high standards required.

Cleaning a vinyl basketball flooring requires a gentle approach to avoid damage while effectively removing dirt and maintaining its appearance. Here’s a step-by-step guide:

1. **Sweep or Vacuum:** Start by removing loose dirt, dust, and debris from the floor surface using a broom or a vacuum cleaner with a soft brush attachment. This step prevents scratching during the cleaning process.

2. **Prepare a Cleaning Solution:**

- Mix a mild detergent or a pH-neutral cleaner with water. Avoid harsh chemicals or cleaners that could damage the vinyl.

- Alternatively, you can use a commercial vinyl floor cleaner, following the manufacturer's instructions for dilution.

3. **Spot Cleaning:** If there are specific stains or spots, apply the cleaning solution directly to those areas. Use a soft cloth or sponge to gently scrub the stains, working in a circular motion.

4. **Mop the Floor:**

- Dip a mop into the cleaning solution and wring it out well. The mop should be damp, not dripping wet.

- Mop the entire floor surface, starting from one corner and working your way towards the opposite side. This ensures even coverage and prevents streaking.

5. **Rinse the Floor (Optional):** If using a detergent-based cleaner, rinse the floor with clean water using a separate mop or sponge. This step removes any residue left by the cleaner.

6. **Dry the Floor:** Use a dry mop, towel, or allow the floor to air dry completely. Ensure no moisture is left standing on the surface, as vinyl can be slippery when wet.

7. **Routine Maintenance:** To keep the vinyl basketball flooring in good condition:

- Regularly sweep or vacuum to remove dirt and debris.

- Clean up spills promptly to prevent staining.

- Avoid using abrasive tools or harsh chemicals that could damage the vinyl.

8. **Protective Measures:** Consider using mats at entry points to reduce dirt being tracked onto the floor, and use furniture pads to prevent scratches.

By following these steps, you can effectively clean your vinyl basketball flooring while preserving its durability and appearance over time.

If I Provide the Pattern, Can You Customize PVC Flooring According to the Pattern?

As the demand for personalized home decor continues to grow, more and more customers are looking to customize PVC flooring based on their own patterns. This customization service not only meets the unique aesthetic needs of customers but also makes the home environment more personalized and distinctive. So, is it feasible to customize PVC flooring according to a pattern provided by the customer? The answer is yes.

Customization Based on Your Sample is Possible

If you have a pattern you love and want to apply it to PVC flooring, we can provide this customization service for you. First, you need to mail your pattern sample to our factory. Please ensure that the pattern on the sample is clear and complete so that we can accurately replicate it on the PVC flooring.

Mailing the Sample and Printing the Sample

Upon receiving your sample, our factory will print a sample according to the pattern on it. This is a critical step, and we will do our best to ensure that the printed sample closely matches the pattern you provided. Once the sample printing is complete, we will send the sample back to you for confirmation.

Sample Confirmation and Production

After receiving the printed sample, please carefully check its quality and the accuracy of the pattern. If you have no objections to the sample, you can confirm the production. Upon your confirmation, our factory will proceed to mass-produce the PVC flooring according to the sample pattern.

Sample Printing Fees

It is important to note that there will be an additional charge for printing the sample. This is because special equipment and materials are needed to ensure the accurate reproduction of the pattern during the sample printing process. The specific amount of the sample printing fee will be detailed after you submit your pattern sample.

Minimum Order Quantity Requirement

To ensure production efficiency and cost-effectiveness, there is a minimum order quantity requirement for custom patterned PVC flooring. The minimum order quantity depends on the complexity of the pattern and the process requirements. We will discuss the specific requirements of the minimum order quantity with you during the sample confirmation process to ensure you are fully informed.

With our professional customization service, you can apply your favorite patterns to PVC flooring, creating a unique home environment. Whether to meet personal decor needs or to achieve a distinctive design in commercial spaces, we can provide you with high-quality custom PVC flooring. If you have any questions or need more information, please feel free to contact us. We look forward to working with you to add unique beauty and personality to your space.

When it comes to installing flooring for sports courts, such as basketball courts, the choice of adhesive is crucial. Given the large area of a basketball court and the high level of activity and foot traffic it experiences, the question arises: can double-sided tape be used for this purpose?

Basketball courts are extensive areas that see intense and frequent use. Players sprint, jump, pivot, and exert significant force on the flooring. Under such conditions, the adhesive must ensure the flooring stays firmly in place without shifting or coming loose. Double-sided tape, while convenient and easy to use, may not provide the level of adhesion required for such high-impact activities.

Here are some reasons why double-sided tape is not recommended for basketball courts:

1. Large Surface Area: Basketball courts cover a substantial area, making it challenging for double-sided tape to provide consistent and secure adhesion throughout the entire surface.

2. High Activity Level: The dynamic and vigorous movements of basketball players demand an extremely durable adhesive. Double-sided tape may not withstand the constant stress and could fail, leading to safety hazards.

3. Durability Concerns: Over time, double-sided tape may lose its adhesive properties, especially in areas subjected to frequent movement. This degradation can cause the flooring to lift or shift, compromising the playing surface's integrity and safety.

For these reasons, using a stronger adhesive, such as glue, is recommended for installing basketball court flooring. Glue provides a much stronger bond and ensures the flooring remains securely in place, even under intense use. Here’s why glue is a better option:

· Stronger Bond: Glue forms a strong, permanent bond with the flooring material and the subfloor, ensuring that the surface remains stable and secure.

· Durability: High-quality sports flooring glue is designed to withstand heavy foot traffic and the stresses of athletic activities, making it more suitable for basketball courts.

· Safety: A securely installed floor reduces the risk of accidents caused by loose or shifting flooring, providing a safer environment for players.

While double-sided tape is not suitable for basketball courts, it can be effectively used for other types of sports courts with less intense activity levels, such as badminton courts. Badminton courts have a smaller surface area and the sport involves less aggressive movements compared to basketball, making double-sided tape a viable option. Here are the advantages in this context:

· Easier Installation: Double-sided tape is easier to apply and allows for quicker installation, which can be beneficial for smaller courts.

· Adequate Adhesion: For sports like badminton, where the flooring does not experience the same level of stress as a basketball court, double-sided tape can provide sufficient adhesion.

· Flexibility: Using double-sided tape allows for easier removal and replacement of the flooring if needed, offering more flexibility for maintenance.

While the convenience of double-sided tape makes it an attractive option for some installations, it is not suitable for basketball courts due to the large area and high level of physical activity involved. The use of strong glue is recommended to ensure the flooring remains securely in place, providing a safe and durable playing surface. For less demanding sports environments like badminton courts, double-sided tape can be a practical and effective solution. Ultimately, the choice of adhesive should be guided by the specific requirements of the sport and the characteristics of the playing surface.

When selecting flooring materials for a specific project, precise measurements are often crucial to ensure minimal waste and optimal fit. One common question that arises is whether the length of each roll of flooring can be customized to specific requirements, such as a roll that is exactly 17 meters long. The answer to this depends on several factors, including the type of flooring and the available inventory.

Customizing Roll Lengths: Possibilities and Limitations

For certain flooring products, especially those available in large rolls, it is possible to accommodate specific length requests. However, this capability is contingent upon the existing stock and the nature of the product. Here’s what you need to know:

Availability of Large Rolls: Some flooring products are stored in large rolls, which can be cut to specific lengths based on customer requirements. If there is sufficient inventory of these large rolls, fulfilling a request for a roll of exactly 17 meters can often be arranged.

Stock Variations: Not every flooring product is kept in large rolls or has the necessary stock to accommodate customized lengths. The availability of specific roll lengths can vary widely depending on the product type, manufacturer, and current inventory levels.

Communication is Key: Given the variations in stock and product availability, it is essential to communicate your specific needs well in advance. By discussing your requirements with the supplier early on, you can determine whether it is feasible to obtain a roll of flooring that meets your exact specifications.

Steps to Ensure Custom Length Availability

To increase the likelihood of obtaining a roll of flooring in your desired length, such as 17 meters, consider the following steps:

Early Consultation: Contact the supplier as soon as possible to discuss your specific length requirements. This allows them to check their inventory and confirm whether they can accommodate your request.

Flexibility: Be prepared to be flexible. If your exact length cannot be met, ask the supplier about alternative solutions, such as combining multiple shorter rolls or opting for a slightly longer roll that can be trimmed on-site.

Special Orders: In some cases, if the product is not available in the desired length, the supplier may be able to place a special order with the manufacturer. This can take additional time, so it’s important to plan accordingly.

Understanding Limitations: Recognize that not all flooring products can be customized due to manufacturing and logistical constraints. Knowing this in advance can help manage expectations and allow you to explore other viable options.

While it is possible to customize the length of flooring rolls for some products, such as obtaining a roll that is exactly 17 meters long, this depends on the specific product and available stock. Early and clear communication with the supplier is essential to determine feasibility and explore all potential options. By understanding the limitations and working closely with your supplier, you can achieve a solution that best meets your project needs.

When selecting vinyl flooring for a passenger vehicle, several factors need consideration, including durability, slip resistance, waterproofing, ease of cleaning, and environmental friendliness. Passenger vehicle flooring must withstand frequent foot traffic and movement, making durability a key consideration. Here are several types of vinyl flooring suitable for passenger vehicles:

Types of Vinyl Flooring Suitable for Passenger Vehicles

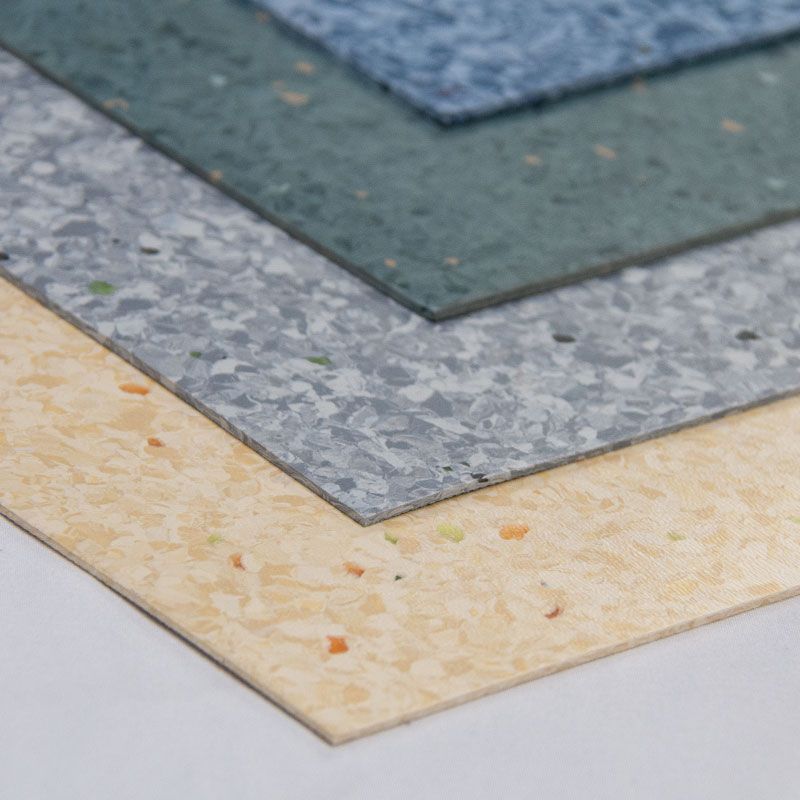

Homogeneous Vinyl Flooring

Homogeneous vinyl flooring is composed of a single layer of vinyl material with uniform thickness throughout. It offers high durability and wear resistance, making it ideal for areas with heavy foot traffic like passenger vehicles.

Heterogeneous Vinyl Flooring

Heterogeneous vinyl flooring consists of multiple layers, including a wear layer, a decorative layer, and a backing layer. It provides both durability and aesthetic appeal, with various design options available. This type of flooring is suitable for passenger vehicles where appearance matters.

Vinyl Sheet Flooring

Vinyl sheet flooring comes in large rolls and offers seamless installation, preventing water infiltration and providing ease of cleaning. It is durable, slip-resistant, and waterproof, making it suitable for passenger vehicles requiring high slip-resistance and waterproofing.

Slip-Resistant Vinyl Flooring

Slip-resistant vinyl flooring is specially designed to provide additional friction on the surface, preventing slips and falls. This type of flooring enhances safety, particularly in wet or slippery conditions, making it suitable for passenger vehicles.

Other Considerations When Choosing Passenger Vehicle Flooring

Durability

Passenger vehicle flooring needs to withstand frequent use without showing signs of wear or damage. Choosing a durable vinyl flooring material ensures longevity and performance under demanding conditions.

Waterproofing

Given the potential for spills and moisture in passenger vehicles, selecting a waterproof vinyl flooring material helps protect the underlying structure and maintain a clean, hygienic environment.

Ease of Cleaning

Passenger vehicle flooring should be easy to clean and maintain to uphold hygiene standards. Opting for vinyl flooring that is resistant to stains and easy to wipe clean simplifies upkeep and ensures a pleasant interior environment.

Environmental Friendliness

Selecting environmentally friendly vinyl flooring materials ensures minimal impact on the environment and passenger health. Look for flooring products that are low in volatile organic compounds (VOC) and made from recycled or sustainable materials.

Conclusion

In conclusion, passenger vehicle flooring should be chosen based on durability, slip resistance, waterproofing, ease of cleaning, and environmental considerations. Homogeneous vinyl flooring, heterogeneous vinyl flooring, vinyl sheet flooring, and slip-resistant vinyl flooring are all suitable options. The specific choice depends on the vehicle's requirements and usage environment to ensure long-term performance and safety.

Add : No.5 Huaqing Intelligent Park, Huishan District, Wuxi, Jiangsu, China

Copyright © 2025 WUXI TEFA DECORATION MATERIAL CO., LTD. All Rights Reserved.

Sitemap | Blog | Xml | Privacy Policy

Network Supported

Network Supported