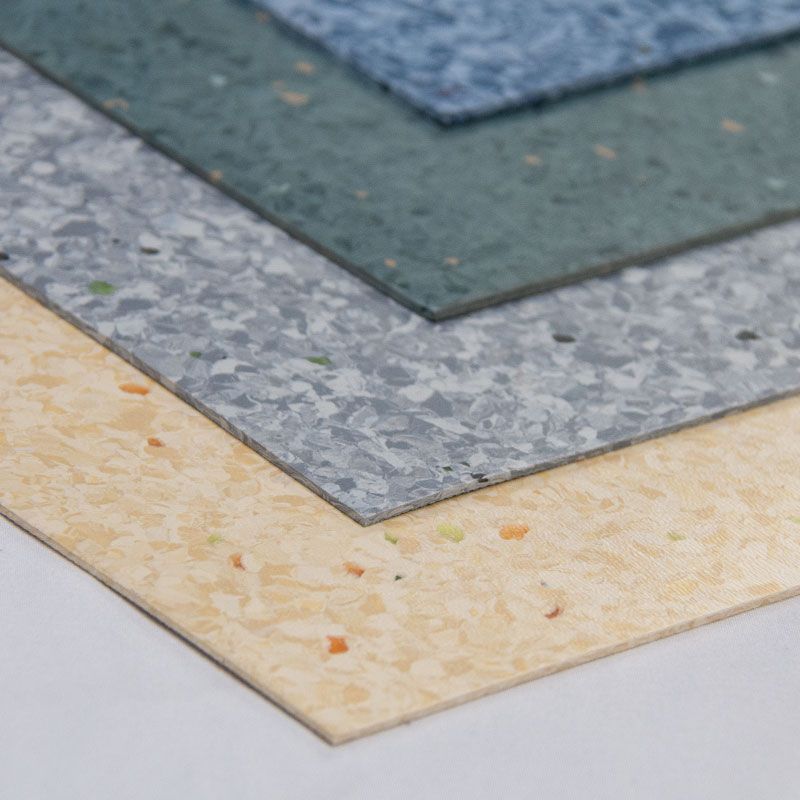

Can PVC Flooring Be Customized to a 3X4 Meter Size?

Jun 26, 2024When considering flooring options, the size and installation method are critical factors that determine suitability. A common question regarding PVC flooring is whether it can be customized to a 3X4 meter size. Due to production equipment limitations, the maximum width for a single piece of PVC flooring is typically 2 meters. Therefore, producing a single 3X4 meter piece of PVC flooring is not feasible. However, this requirement can still be met by using a welding technique.

The production process of PVC flooring involves advanced machinery with strict specifications. Most commonly available PVC flooring production lines have a maximum width capacity of 2 meters. This means that a single piece of PVC flooring cannot exceed this width. Consequently, directly producing a 3X4 meter flooring piece is not possible with current equipment.

Although the maximum width of a single PVC flooring piece is 2 meters, professional welding techniques can seamlessly join multiple pieces to achieve larger dimensions. The welded flooring not only appears seamless but also maintains the same functionality and durability as a single piece. Here are some key advantages of welded PVC flooring:

1. Seamless Appearance:

- Professional welding techniques can make the seams between flooring pieces nearly invisible, ensuring a uniform and aesthetically pleasing look. This is particularly important for large spaces such as exhibition halls and sports arenas.

2. Enhanced Durability:

- Welding not only joins the flooring pieces but also enhances their durability and tensile strength, making the flooring more robust and long-lasting.

3. Water and Dust Resistance:

- Welded flooring has excellent water and dust resistance, helping to maintain cleanliness and hygiene. This is especially beneficial in environments with high sanitary requirements, such as hospitals and laboratories.

4. Flexibility:

- Welding allows for flexible adjustment of flooring dimensions and shapes according to specific needs, accommodating various unique installation requirements.

To ensure that the welded PVC flooring meets expected standards, here are some important considerations during the welding process:

1. Professional Equipment and Technicians:

- The welding process requires specialized equipment and experienced technicians to ensure the quality and effectiveness of the welds.

2. Clean and Flat Surface:

- The flooring surface must be clean and flat before welding to prevent impurities from affecting the weld quality.

3. Controlled Welding Temperature and Speed:

- Proper control of welding temperature and speed is crucial. Incorrect temperature or speed can compromise the quality of the weld.

4. Regular Inspection and Maintenance:

- Welded flooring should undergo regular inspection and maintenance to ensure its long-term stability and aesthetic appeal.

While PVC flooring cannot be directly produced in a 3X4 meter size, welding techniques can achieve this requirement and ensure that the welded flooring meets high standards in aesthetics, durability, and functionality. By choosing professional welding services, you can satisfy the need for large-sized flooring and receive a high-quality flooring solution. Therefore, if you need customized large-size PVC flooring, welding is undoubtedly an ideal choice.

Add : No.5 Huaqing Intelligent Park, Huishan District, Wuxi, Jiangsu, China

Copyright © 2025 WUXI TEFA DECORATION MATERIAL CO., LTD. All Rights Reserved.

Sitemap | Blog | Xml | Privacy Policy

Network Supported

Network Supported